From 2017-18 to 2021-22, Gross expenditure of Rs. 1.08 lakh crore incurred on RRSK works

Electronic Interlocking Systems with centralized operation of points and signals provided at 6427 stations Interlocking of Level Crossing Gates has been provided at 11093 level Crossing Gates Complete Track Circuiting of stations to enhance safety for verification

Electronic Interlocking Systems with centralized operation of points and signals provided at 6427 stations

Interlocking of Level Crossing Gates has been provided at 11093 level Crossing Gates

Complete Track Circuiting of stations to enhance safety for verification of track occupancy by electrical means has been provided at 6377 stations

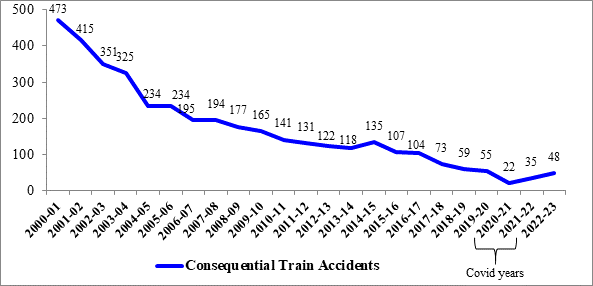

The details of number of consequential train accidents from 2000-01 to 2022-23 are given below :-

As is evident from the graph above, there is a steep decline in the number of consequential train accidents from 473 in 2000-01 to 48 in 2022-23.

The average number of consequential train accidents during the period, 2004-14 was 171.1 per annum, while the average number of consequential train accidents during the period, 2014-23 is 70.9 per annum.

(b): The following efforts are being made by Government to prevent rail accidents: –

- Rashtriya Rail Sanraksha Kosh (RRSK) has been introduced in 2017-18 for replacement/renewal/upgradation of critical safety assets, with a corpus of ₹ 1 lakh crore for five years. From 2017-18 till 2021-22 a Gross expenditure of ₹ 1.08 lakh crore was incurred on RRSK works.

- Electrical/Electronic Interlocking Systems with centralized operation of points and signals have been provided at 6427 stations upto 31.05.2023 to eliminate accident due to human failure.

- Interlocking of Level Crossing (LC) Gates has been provided at 11093 level Crossing Gates up to 31.05.2023 for enhancing safety at LC gates.

- Complete Track Circuiting of stations to enhance safety for verification of track occupancy by electrical means has been provided at 6377 stations upto 31.05.2023.

- Detailed instructions on issues related with safety of Signalling e.g. mandatory correspondence check, alteration work protocol, preparation of completion drawing, etc. have been issued.

- System of disconnection and reconnection for S&T equipment as per protocol has been re-emphasized.

- All locomotives are equipped with Vigilance Control Devices (VCD) to ensure alertness of Loco Pilots.

- Retro-reflective sigma boards are provided on the mast which is located between two OHE masts prior to the signals in electrified territories to warn the crew about the signal ahead when visibility is low due to foggy weather.

- A GPS based Fog Safety Device (FSD) is provided to loco pilots in fog affected areas which enables loco pilots to know the distance of the approaching landmarks like signals, level crossing gates etc.

- Modern track structure consisting of 60kg, 90 Ultimate Tensile Strength (UTS) rails, Prestressed Concrete Sleeper (PSC) Normal/Wide base sleepers with elastic fastening, fanshaped layout turnout on PSC sleepers, Steel Channel/H-beam Sleepers on girder bridges is used while carrying out primary track renewals.

- Mechanisation of track laying activity through use of track machines like PQRS, TRT, T-28 etc to reduce human errors.

- Maximizing supply of 130m/260m long rail panels for increasing progress of rail renewal and avoiding welding of joints, thereby ensuring safety.

- Laying of longer rails, minimizing the use of Alumino Thermic Welding and adoption of better welding technology for rails i.e. Flash Butt Welding.

- Monitoring of track geometry by OMS (Oscillation Monitoring System) and TRC (Track Recording Cars).

- Patrolling of railway tracks to look out for weld/rail fractures.

- The use of Thick Web Switches and Weldable CMS Crossing in turnout renewal works.

- Inspections at regular intervals are carried out to monitor and educate staff for observance of safe practices.

- Web based online monitoring system of track assets viz. Track database and decision support system has been adopted to decide rationalized maintenance requirement and optimize inputs.

- Detailed instructions on issues related with safety of Track e.g. integrated block, corridor block, worksite safety, monsoon precautions etc. have been issued.

- Preventive maintenance of railway assets (Coaches & Wagons) is undertaken to ensure safe train operations and to keep a check on Rail Accidents across the country.

- Replacement of conventional ICF design coaches with LHB design coaches is being done.

- All unmanned level crossings (UMLCs) on Broad Gauge (BG) route have been eliminated by January 2019.

- Safety of Railway Bridges is ensured through regular inspection of Bridges. The requirement of repair/rehabilitation of Bridges is taken up based upon the conditions assessed during these inspections.

- Indian Railways has displayed Statutory “Fire Notices” for widespread passenger information in all coaches. Fire posters are provided in every coach so as to inform and alert passengers regarding various Do’s and Don’ts to prevent fire. These include messages regarding not carrying any inflammable material, explosives, prohibition of smoking inside the coaches, penalties etc.

- Production Units are providing Fire detection and suppression system in newly manufactured Power Cars and Pantry Cars and Fire and Smoke detection system in newly manufactured coaches. Progressive fitment of the same in existing coaches is also underway by Zonal Railways in a phased manner.

- Regular counseling and training of staff is undertaken.

The number of Consequential train accidents has decreased from 59 in 2018-19 to 48 in the year 2022-23. The details of Consequential train accidents during the last five years are given below:

| Year | Number of consequential Train Accidents | |

| 2018-19 | 59 | |

| 2019-20 | 55 | |

| 2020-21 (Covid year) | 22 | |

| 2021-22 (Covid year) | 35 | |

| 2022-23 | 48 |

The Government is using the following new techniques or devices to prevent train accidents:-

1. With a view to provide safer and more comfortable journey to the travelling passengers, Linke Hofmann Busch (LHB) coaches are being inducted in IR in a phased manner. Trains operating with conventional ICF coaches are getting replaced by LHB coaches in a phased manner. Around 1241 rakes are running with LHB coaches (including new introduction).

2. Improved safety standards have been adopted in Vande-Bharat trains, which include Train Collision Avoidance System (Kavach), Fully Sealed Gangway for Free Passenger Movement, Automatic Plug Doors, emergency openable Windows and fire extinguisher in each coach, CCTVs in all Coaches, Emergency Alarm Push buttons and Talk Back Units in all Coaches, Better fire safety- Aerosol based fire detection and suppression system etc.

3. Steps have been taken to improve fire safety measures. All Power Cars, Pantry Cars and AC coaches are being equipped with suitable fire safety measures in phased manner.

4. Production Units are providing Fire detection and suppression system in newly manufactured Power Cars and Pantry Cars and Fire and Smoke detection system in newly manufactured AC coaches. Progressive fitment of the same in existing coaches is also underway by Zonal Railways in a phased manner.

5. Technological upgradation in safety aspects of coaches and wagons, by way of introducing Modified Centre Buffer Couplers, improved suspension design and provision of Automatic fire & smoke detection system in coaches, is being carried out which would eventually lead to enhanced safety standards. Apart from these upgradations in Rolling Stock design and its components, Indian Railways is also installing Wheel impact Load Detectors (WILD), Hot Box Detector (HBD), Oscillation Monitoring System (OMS) etc. in a phased manner to improve safety of coaches and wagons.

6. Indigenously developed automatic train protection system “KAVACH” has been adopted as an aid to driver in train running within specified limits and also help the train running during inclement weather. KAVACH is being provided progressively over Indian Railways.

This information was given by the Minister of Railways, Communications and Electronic & Information Technology, Shri Ashwini Vaishnaw in a written reply to a question in Rajya Sabha today.

—-

English

English French

French German

German Italian

Italian